The role of the pressure die is two-fold.

To control the axial tube motion, the pressure die applies axial force to the tube either through friction (between pressure die and tube) or through an optional boost block (as shown), which pushes against the back of the tube during bending. The rotation is continued until a desired tube bend angle is reached.

With the tube in place, the bend die and clamp die then rotate around as one piece, bending the tube around the bend die, with the pressure die maintaining pressure against the wiper, and moving along in the axial direction at a prescribed percent boost. It is then locked in place by closing of the clamp die onto the bend die. To bend a tube in a rotary-draw bender, it is first positioned inside the bender. The figure below illustrates a rotary draw tube bending process along with the names of the tooling used.

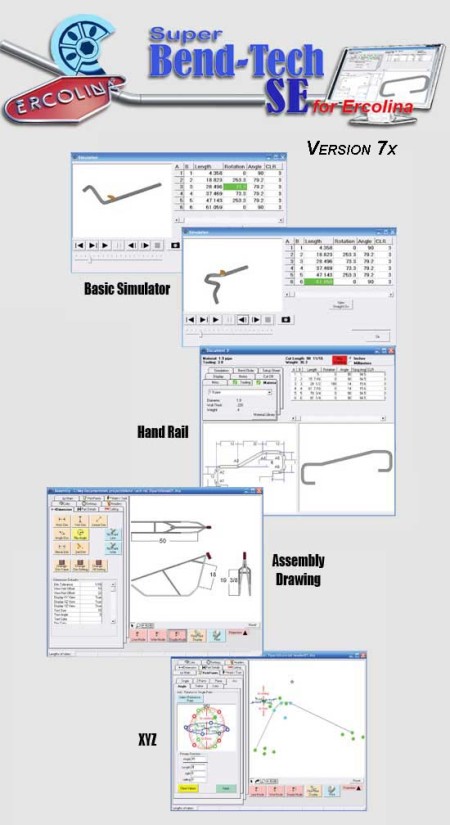

Tube bending software trial#

Having the means to predict tube geometry after bending is useful as a manufacturing aid since it can reduce trial and error during prototyping.

The computer model also estimates the force and torque required to bend tubes to a given radius. I also studied the physics of bending tubes and developed a computer program to predict the stresses, strains, wall thickness, and springback of a tube after bending. For my Master's degree project I researched rotary draw tube bending which is a common method used to bend tubes. Tube bending is a general term used to describe the metal forming process used to permanently form tube or pipe.

0 kommentar(er)

0 kommentar(er)